Reduce time and effort with ApogeeAero® Roller Casing Spacers

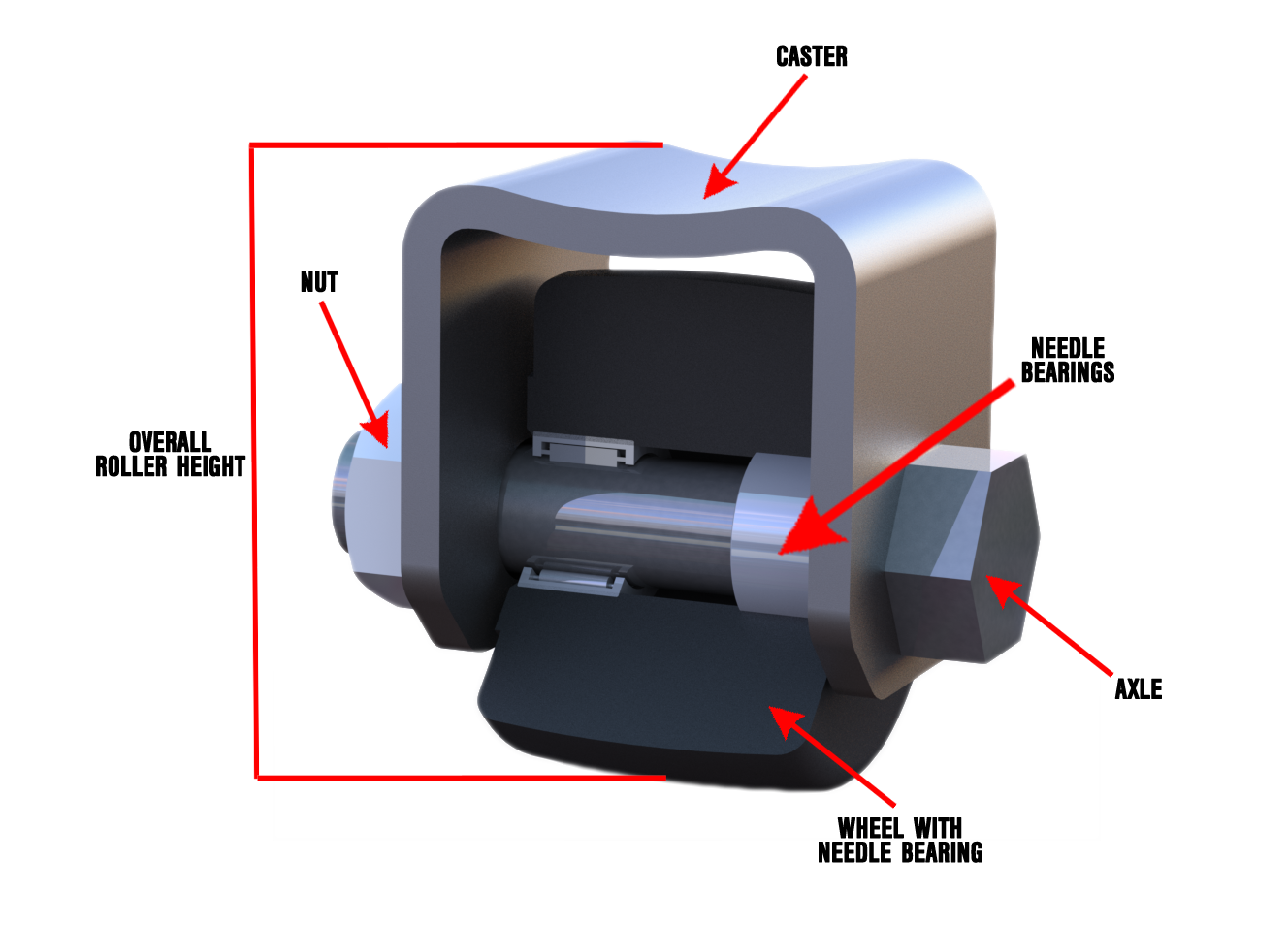

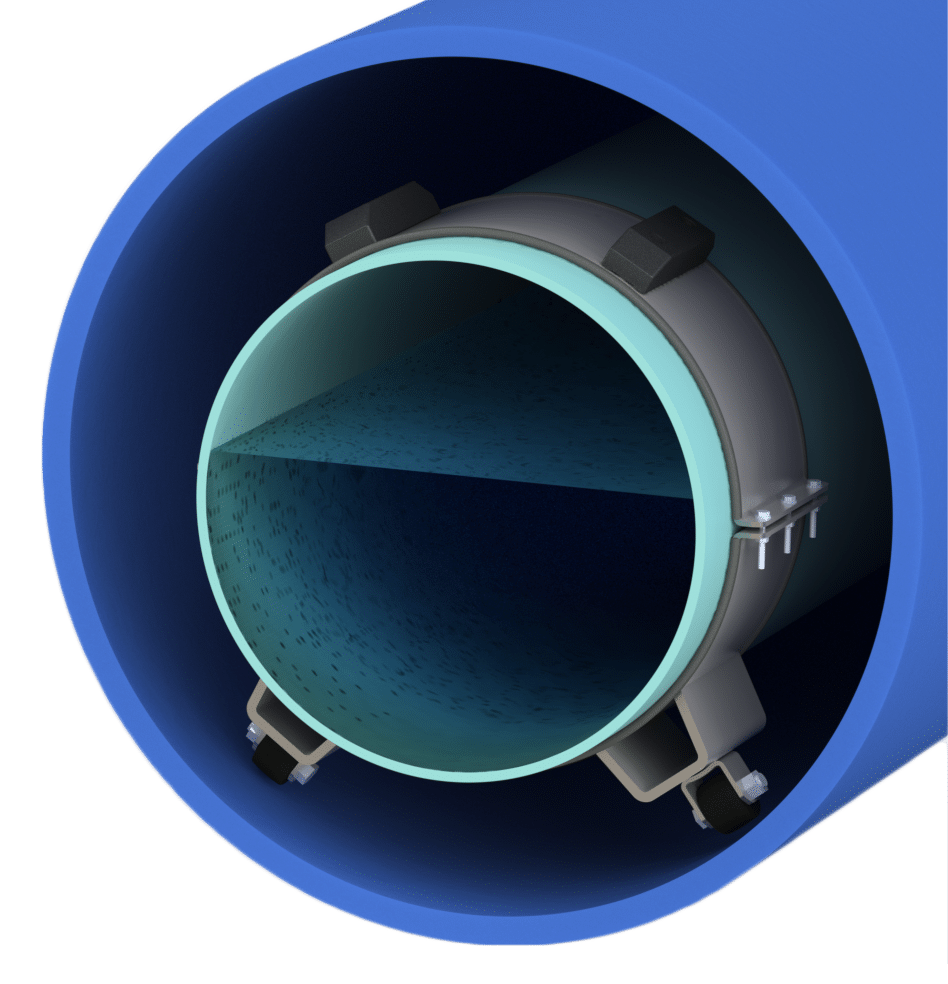

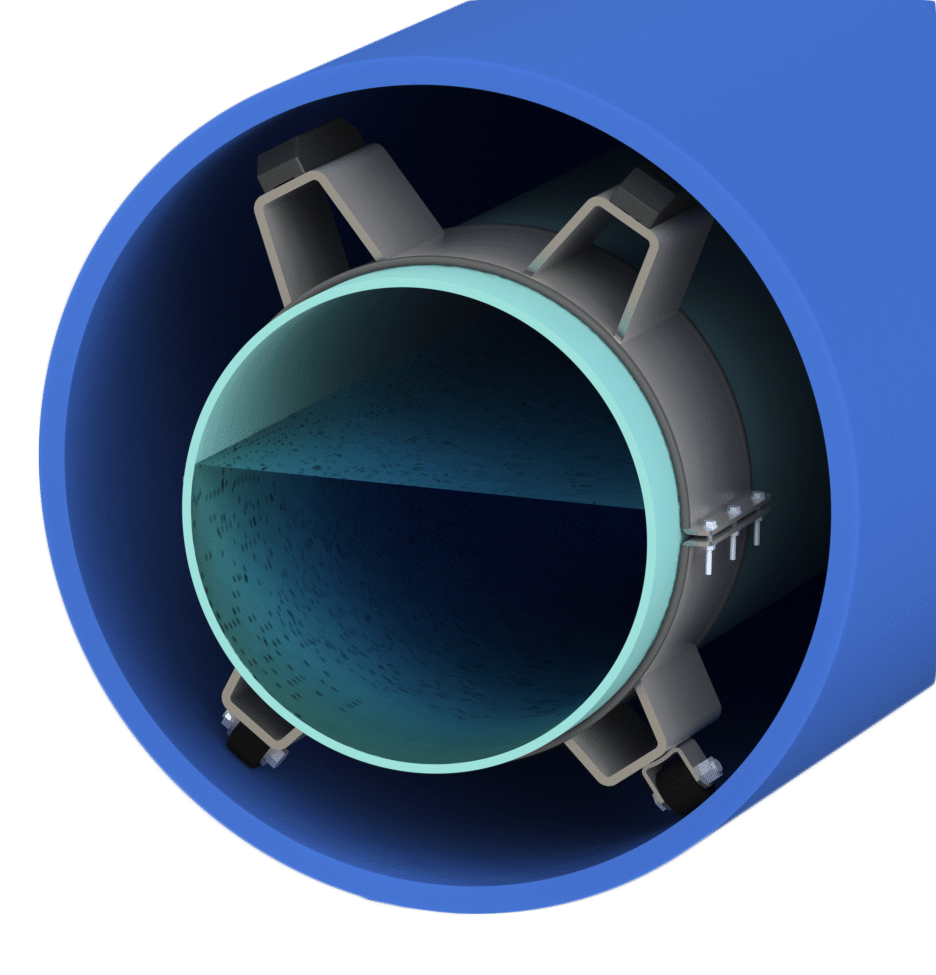

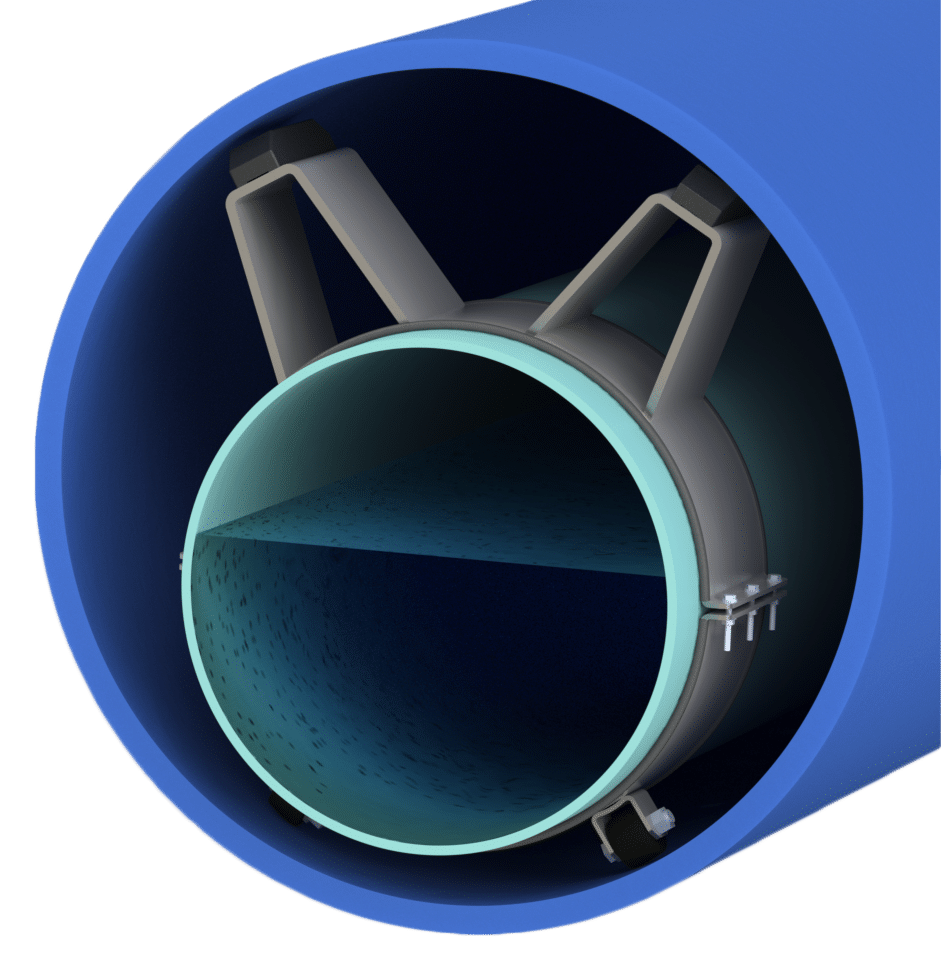

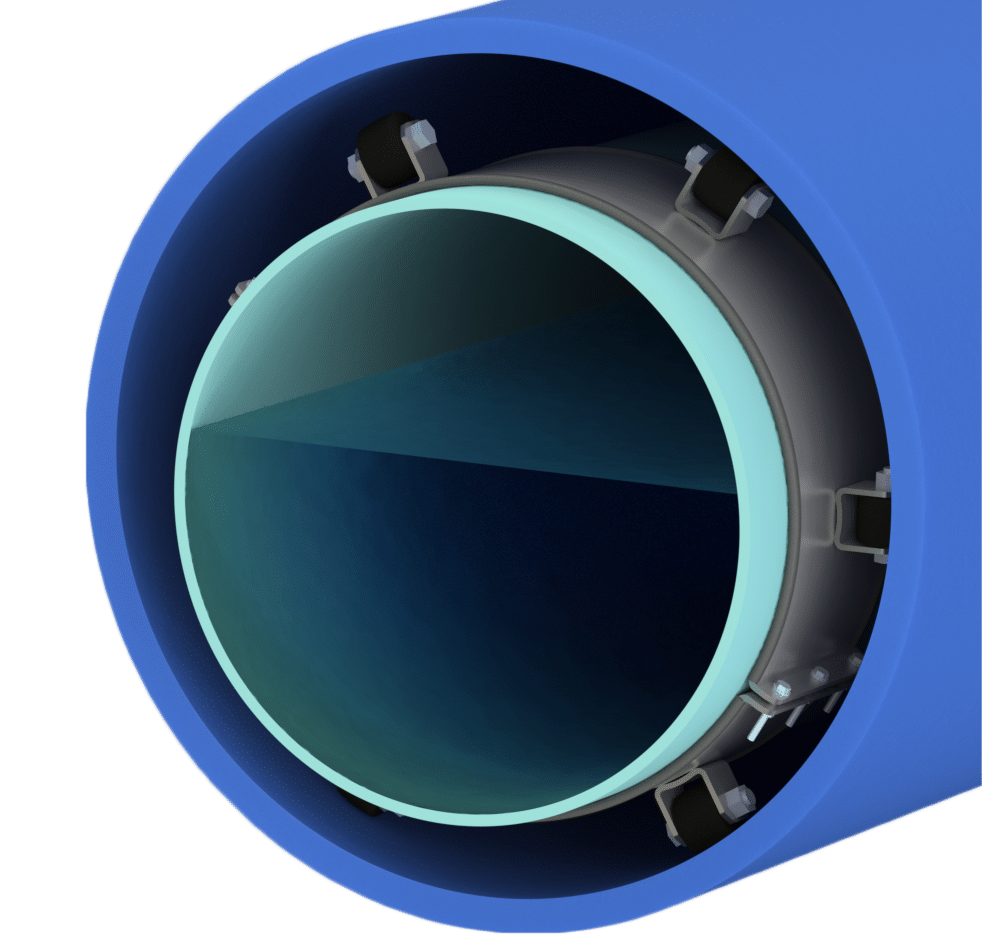

APS offers ApogeeAero® Roller Casing Spacers with a revolutionary anti-corkscrewing feature specifically designed to fit into a smaller annular space while upholding higher load strengths than any other low-profile, high-load casing spacer roller offered on the market.

Anti-corkscrewing rollers are available in 4 sizes, ranging from small to extra-large, with dynamic loads up to 6,000 lbs. and static loads up to 12,500 lbs. per roller.

Related Documents

Brochures

Specifications

Product Installation Instructions

Product Ordering Instructions

Cost-Effective & Efficient

These low-profile, high-strength anti-corkscrewing rollers are cost competitive to traditional runners while still cathodically isolating the carrier pipes from the casing pipe.

Not only are they cost competitive, but they can carry heavy loads while reducing the coefficient of friction from .2 to .06 which is 70% less, thus increasing the average installation speeds from 3-5 ft. per minute to 15+ ft. per minute, reducing the size of equipment necessary to install carrier pipes & labor costs needed to push or pull carrier pipes.

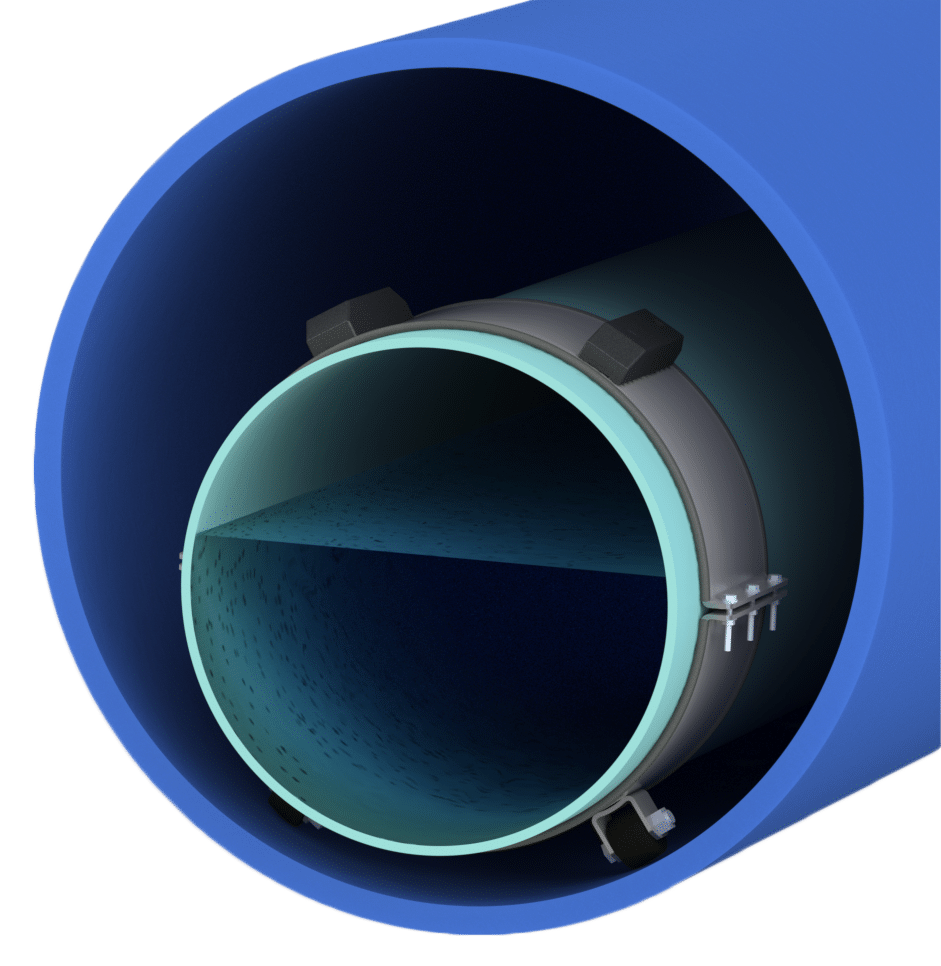

Carrier pipe pushes are installed 5 to 7 times or more faster than casing spacers with runners and require no greasing of the casing pipe I.D.’s as many contractors typically do.

A Variety of Specifications for Your Application

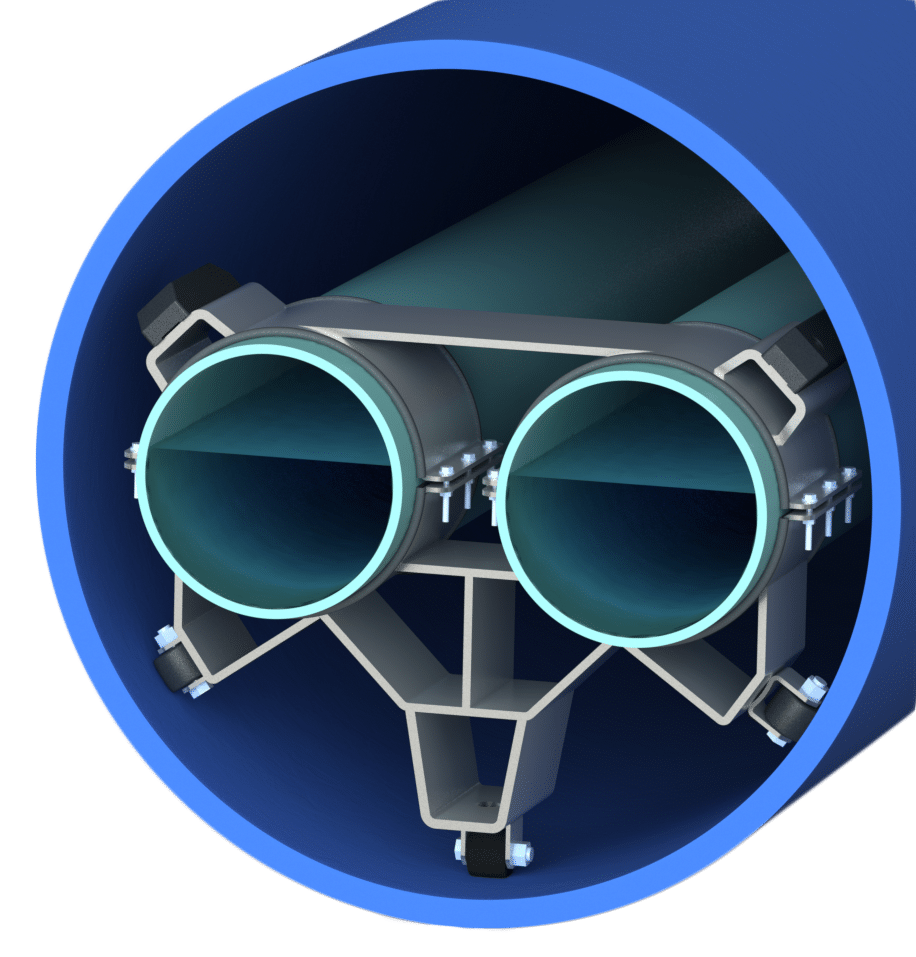

APS manufactures anti-corkscrewing roller casing spacers in various sizes to accommodate pipe diameters from 4 inches to 120 inches or larger and can satisfy specific customer requirements for practically every carrier pipe application, such as positioning multiple carriers or clusters with one casing, centering small carriers within large casing, positioning thermally insulated pipe without damaging the insulation, positioning gravity sewer to on-grade requirements, and much more.