Flange Isolating Gasket Kits

Flanges can be one of the most common trouble areas in a CP System. Flanges need to be sealed properly to prevent leakage and must be cathodically isolated to prevent stray currents which cause undo corrosion and eventual breakdown of the metal.

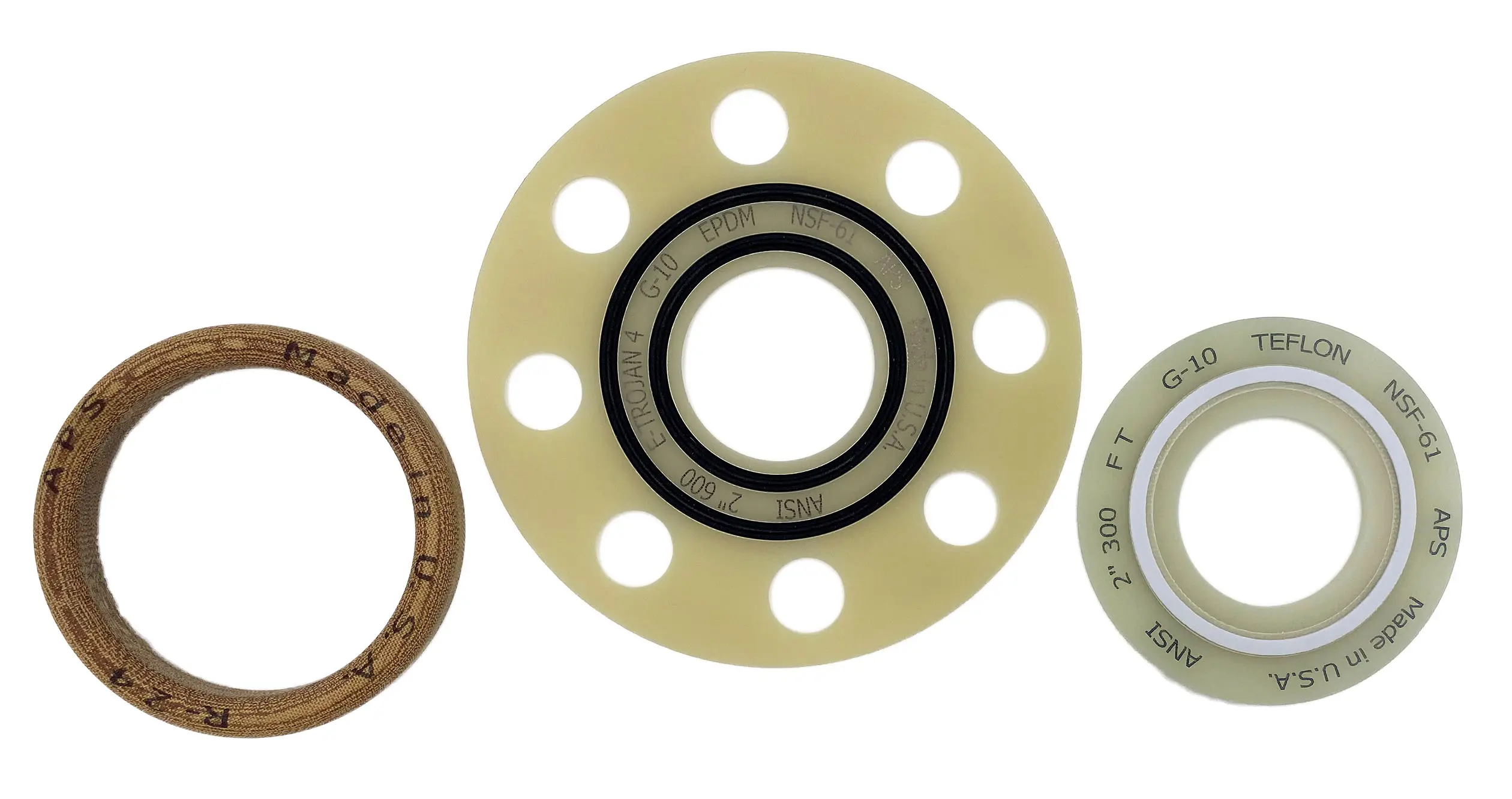

APS manufactures and maintains a supply of quality products and materials which help solve most flange sealing problems, therefore preventing subsequent corrosion and saving the integrity of the pipeline. APS Flange Isolation Gasket Kits are manufactured according to ANSI B16.5 specifications up to 24″. Above 24″, please provide the specifications of your flange using our convenient worksheet. Technical assistance is available upon request.

Flange Isolating Gasket Kit Materials Available:

Related Documents

Brochures

Specifications

Product Installation Instructions

Additional Resources

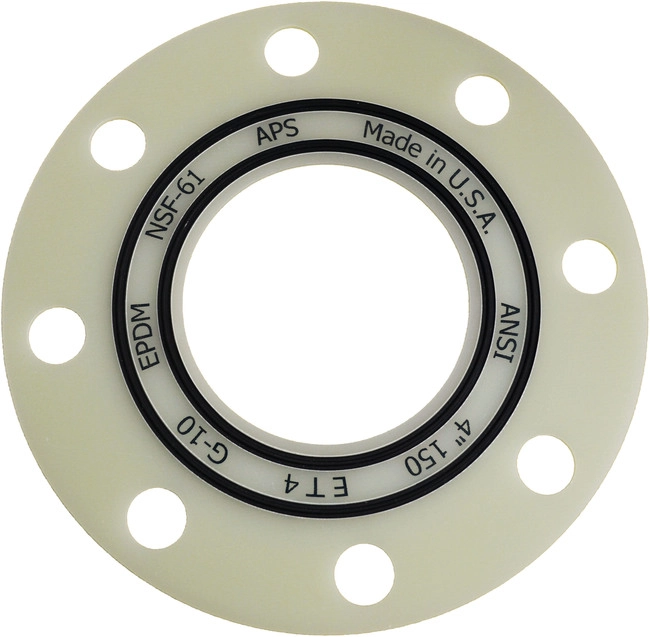

Trojan Sealing Gaskets

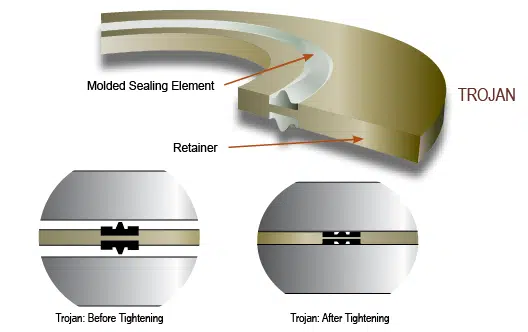

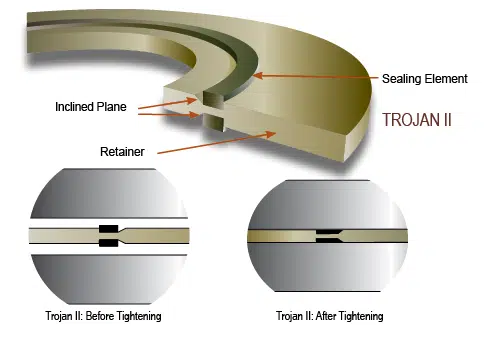

Trojan gaskets are state-of-the-art in near zero leakage static sealing. The elastomer sealing element is encapsulated in the electrically isolated retainer. The encapsulation of the sealing element permits only microexposure of the seal to hostile environments of fire, chemicals and corrosive fluids.

The controlled confinement of the elastomer sealing ring within the retainer allows for the availability of a 92% to 94% volume filled groove. A consistent controlled pressure seal can always be obtained without tremendous bolt loads. Reduced loads allow for reduced flange thickness with smaller circles and smaller bolt holes.

The cross section of APS’ Trojan Sealing Gasket shows the elastomer sealing element as it appears before compression between flanges. This compression causes the seal to effectively fill the void of the groove and encapsulate, permitting only micro exposure of the actual seal to hostile elements either from within or without.

Duplex Seal Trojan

Four seals on the Duplex-Seal Trojan further ensure the integrity of the sealing capability of an already proven reliable gasket. For areas where absolute zero leakage is a must, the Duplex-Seal Trojan works twice as hard.

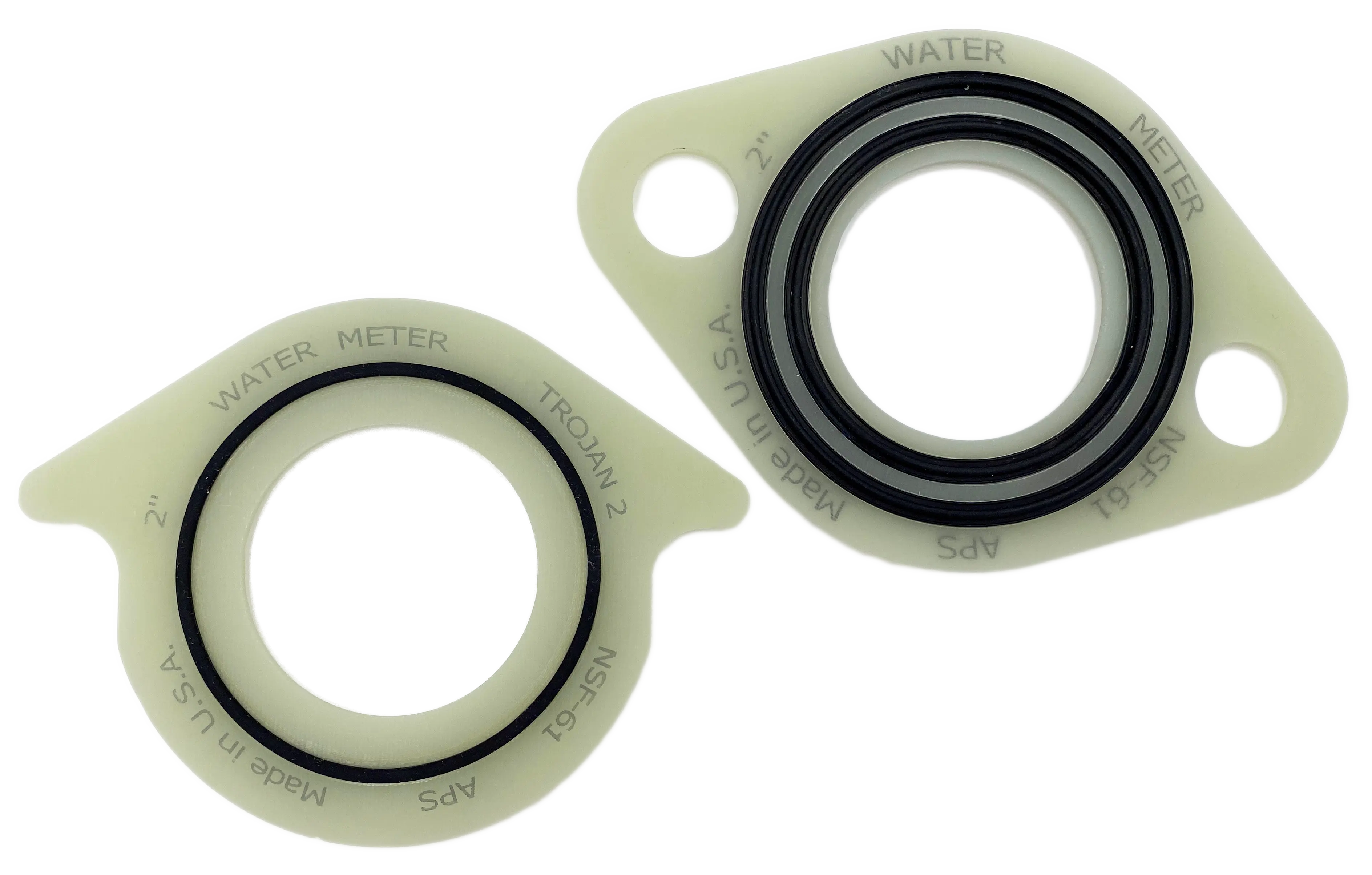

Trojan Water Meter

Trojan G-10 cathodic water meter isolating gaskets are NSF-61 approved and state of the art in near zero leakage static sealing for use in preventing galvanic reaction from the use of dissimilar metals on water piping such as steel or cast iron to brass. The elastomer sealing element is encapsulated in the electrically isolating retainer. The encapsulation of the sealing element permits only microexposure of the seal to potable water flow. G-10 Gasket Kits are designed to keep any and all electrical currents from running back to the water meter.

Seal Materials Available:

Integra® Series

Extreme Temperature Applications

- Isolating between flanges of dissimilar metals to prevent galvanic corrosion

- Wellhead isolation from inter-connected flow lines

- Mating mismatched dissimilar flanges

- Eliminate turbulence and flow-induced erosion between ring-joint (RTJ) flanges

- Protect against corrosion on uncoated or scarred flange faces

- Seal between flanges subjected to vibration/cavitations

- Eliminate corrosion from forming in the cavities between RTJ flanges where intense modes of hostile chemicals may be present

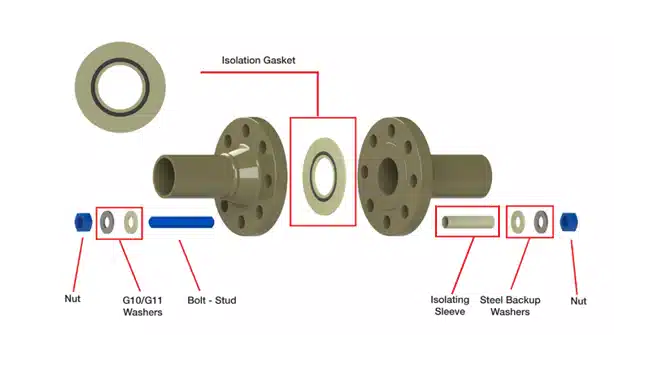

Flange Isolating Gasket Kit Sleeves & Washers

Isolating sleeves and washers are manufactured in various materials and sizes to meet every customer’s needs. Also available are one-piece integral sleeves and washers which are made of Minlon, providing superior compression strength. G-10 Integral sleeves are available in sizes through 1-1/2” and Minlon Integral sleeves are available in sizes through 1”. A variety of high temperature sleeves are also stock items.

With each isolating washer, an S.A.E. electroplated steel washer is provided to protect the isolating washer from damage by the nut. APS flange isolating gasket kits are available in single or double washer kits.

Sleeves available in:

Washers available in:

Flange Isolating Gasket Kit Packaging

Each APS Flange Isolation Gasket Kit is packaged individually in durable corrugated boxes. Isolating sleeves and washers are packaged separately and are cushioned within the box to protect them from damage during shipment.

Each set is clearly tagged with flange size, pressure rating, type of isolating sleeve, and whether it is a single washer or double washer set. A recommended bolt tightening sequence sheet is provided with each kit.