Casing End Seals

Advance Products & Systems Casing End Seals outperform the costly and labor-intensive brick and mortar method of sealing casing ends.

While soil stress and pipe movement cause mortar to crack, the APS end seals move with the pipe, ensuring the integrity of the seal. And, unlike link-type sealing blocks that are limited to carrier/casing and can only be used on a concentric profile, the APS end seals are fully flexible.

An end seal is a 1/8″ thick synthetic rubber seal that eliminates foreign material from entering the annular space between a carrier pipe and a casing pipe.

APS offers six types of end seals that can accommodate any combination of pipe sizes.

Benefits:

Related Documents

Brochures

Product Installation Instructions

Casing End Seals – Models for Every Application

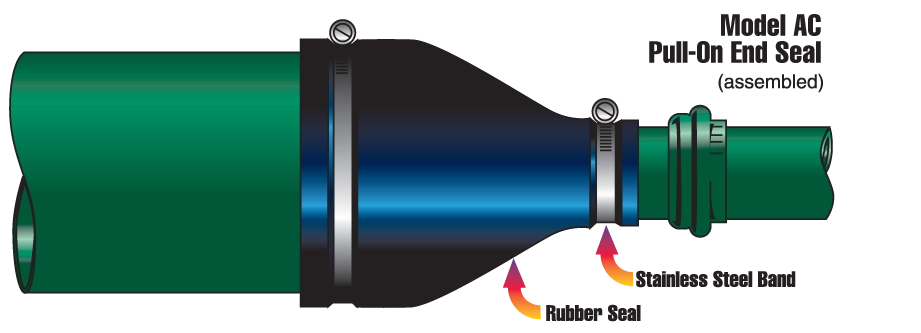

Model AC end seals (seamless pull-on) can be produced in concentric (for centered pipes) and eccentric (for non-centered pipes). Seamless & conform to the pipe eliminating any water seepage.

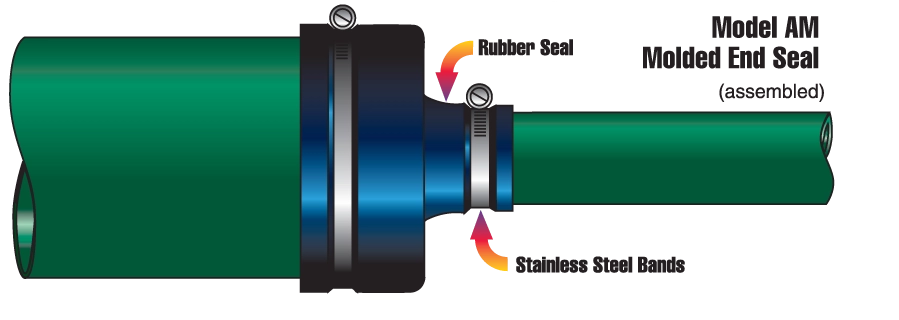

Model AM end seals (molded) tightly conforms to the O.D. of the casing & carrier pipe to form a water-tight seal greater than our other models offered.

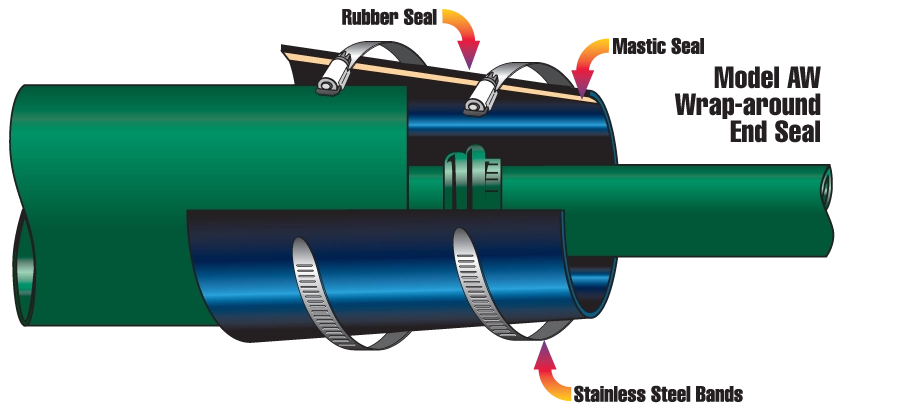

Model AW end seals (wrap-around) can be produced in concentric (for centered pipes) and eccentric (for non-centered pipes). They can also be used to facilitate existing installations where the carrier pipe has already been installed in the casing and the pipeline is complete.

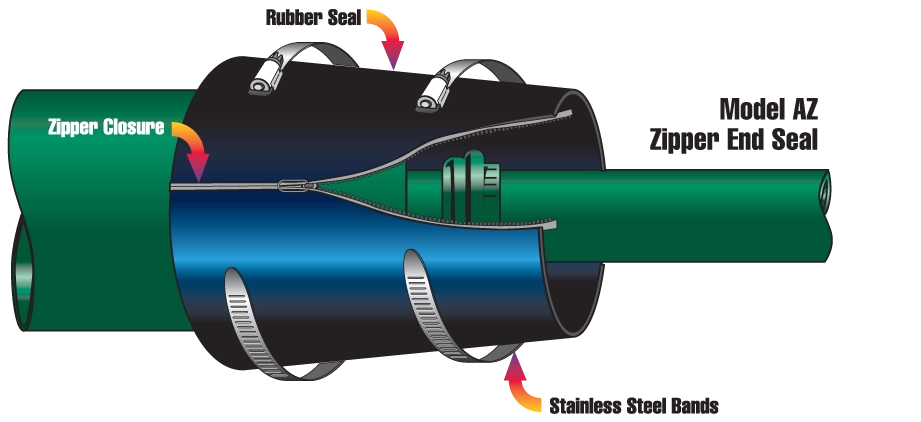

Model AZ end seals (zipper) are produced for concentric (for centered pipes) and eccentric (for non-centered pipes). They are used to facilitate installation when the carrier line has already been installed and the pull is complete. They are used on new & existing casing that require modifications or extensions. The Stainless Steel zippers are pressure molded to the rubber and feature a protective rubber strip attached to the seal under the zipper to prevent damage or abrasion to the pipe. The zipper casing end seals can be removed and reinstalled without damaging the seal.

Model AMCE end seals (molded cone) are equipped with easy-to-read size indicators for versatile installation on a variety of carrier sizes. The closed conical feature allows for low storage cost as each size can cover a range of carriers.

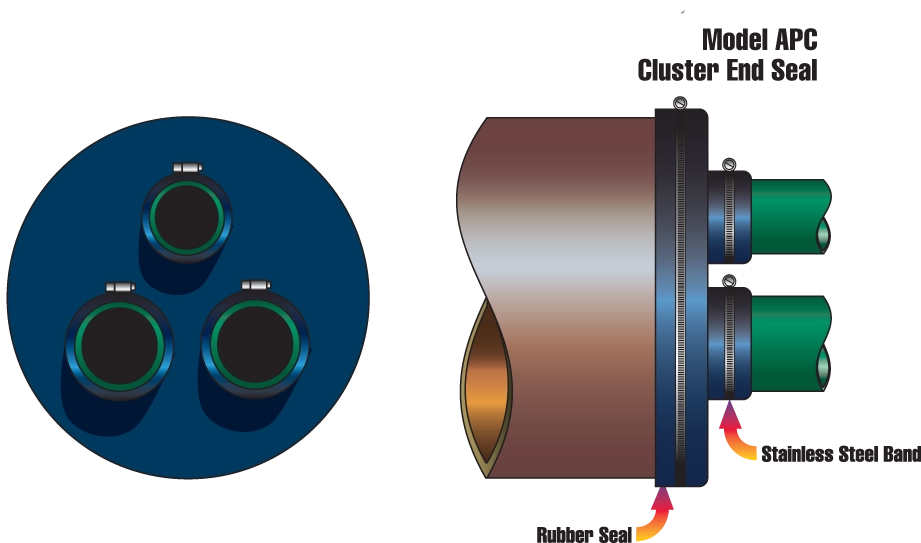

Model APC end seals (cluster) are our only option for multi-carrier installations.

All six options are made of 1/8″ thick synthetic rubber assuring excellent chemical resistance and resiliency and are secured with stainless steel banding straps with a 100% non-magnetic worm gear mechanism to insure the integrity of the clamp. Only a screwdriver is required for installation.

In addition, Innerlynx® form a mechanical seal between pipelines and casing. Innerlynx® form a hydrostatic seal and electrically insulate the carrier pipe from the casing. Innerlynx® can be installed by one person and require no special tools.