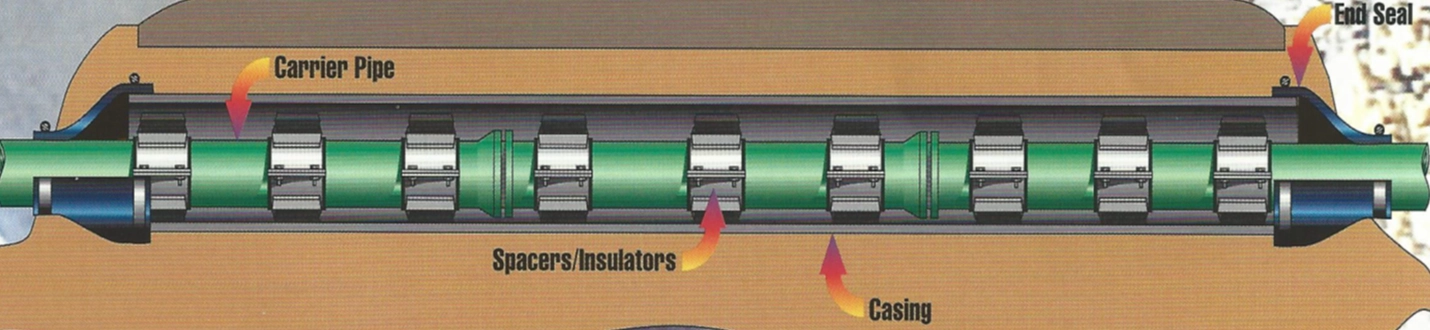

Casing Spacers

APS offers a proven solution with Casing Spacers to outperform the labor intensive, unreliable use of wooden skids.

Casing Spacers center water and sewer pipes in casings with easy installation, are virtually corrosion proof, and provide insulating protection from a possible electrical shorting between the carrier pipe and casing pipe. No special tools or grease needed, and they are easily bolted on by a single worker.

Related Documents

Brochures

Product Installation Instructions

Product Ordering Instructions

Save Time & Labor

APS Casing Spacers eliminate the need to fill the casing annulus with sand which is extremely labor intensive. Sand in the annulus also acts as an electrolyte thereby introducing unwanted current to the steel or ductile iron.

Eliminating the annular fill allows for easy removal to repair or replace damaged pipes. With no need for this fill, APS Casing Spacers are your answer to lower installation costs with continued access for maintenance.

Installing Casing Spacers

Casing insulators are used to support and electrically isolate a pipeline from a casing pipe through which it must pass and are used in river crossings, canal crossings and bridge crossings as well as highway and railroad crossings.

We recommend installation of casing spacers every 6 to 8 feet.

Options Available

STAINLESS (MODEL SSI) & CARBON STEEL (MODEL SI) SPACERS

Heavy duty two-piece stainless steel or carbon steel bands by APS serve virtually every piping application and should be utilized inside casing that is 2 or 3 pipe sizes larger than the carrier pipe.

APS steel band casing is available in two widths: 8″ width is recommended for carrier pipe 4″ to 24″; 12″ width for carrier pipes 26″ to 120″ and larger. The band is constructed of 14 gauge steel with a 90 mil EPDM liner. Stainless steel spacers are available in grade 304L. Carbon steel spacers are available with a thermoplastic powder coating for extra corrosion protection. Stainless steel and carbon steel spacers are available for pipe diameters 4″ – 144″.

INJECTION-MOLDED POLYETHYLENE SPACERS

APS casing insulators are manufactured from injection molded high density virgin polyethylene. Benefits of polyethylene include high impact strength as well as abrasion resistance.

Once installed, the low friction of polyethylene facilitates easy installation into the casing. Molded into the inner surface are grooves which prevent slippage of any carrier pipe coating.

APS casing insulators have excellent dielectric resistance and low moisture absorption which yields minimal electric current loss and no impairment of cathodic protection. Sizes are available from 1″ through 60″ with a standard runner height of 1″. Casing insulators from 1″ through 12″ comprise two halves; two pi and four pi sections make up 14″ and above. APS casing insulators are lightweight, economical and easy to install. Only a screwdriver is required for installation.

CUSTOM FABRICATION

APS is capable of manufacturing casing spacers and end seals for specific customer requirements. Our engineering staff has experience in the following: